Failure Analysis

Houston Electron Microscopy is well equipped to conduct complete failure analysis of metallic components. The most common forms of material failures are fracture, corrosion, wear, and deformation. Our SEM/EDS system allows for the microscopic study of where failures initiate and help determine the cause of failure. Our SEM/EDS system allows for the microscopic study of where failures initiate and help determine the cause of failure. For non-metals, our Scanning Electron Microscope can operate in Low Vacuum mode, which neutralizes charges on uncoated, non-conducting materials so that gold coating is not required for plastics, ceramics, and other dielectrics. However for more delicate or organic materials, gold sputtering is available. Additionally micro FT-IR is used for analyzing organic materials such as polymers, coatings, fibers, rubbers, cement, geological samples, and pharmaceutical samples. micro-FTIR is also used to identify unknown materials and may also be helpful in the investigation of failure analysis.

Failure Analysis, Causes and Failure Types

Houston Electron Microscopy is well equipped to conduct complete failure analysis of metallic and non-metallic components. The most common forms of material failures are fracture, corrosion, wear, and deformation.

A fracture of a workpiece during forming can result from flaws in the metal; these often consist of nonmetallic inclusions such as oxides or sulfides trapped in the metal during refining. Laps are another type of flaw, in which part of a metal piece is inadvertently folded over on itself but the two sides of the fold are not completely welded together. Structural and machine parts subject to vibrations and other cyclic loading must be designed.

Fracture

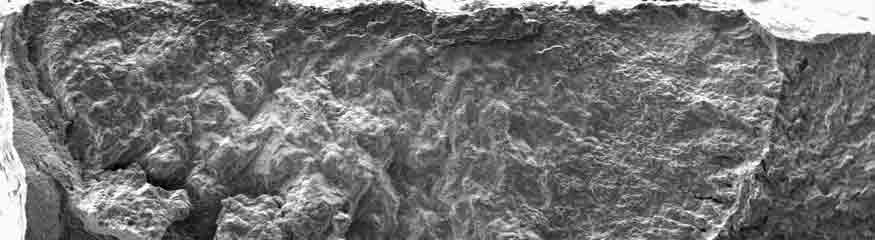

Fracture Low Magnification of 40X

Brittle Failure

Brittle failure occurs when there is a breakage of a material due to a sudden fracture. When a brittle failure occurs, the material breaks suddenly instead of deforming or straining under load. The fracturing or breaking can occur with only a small amount of load, impact force or shock.

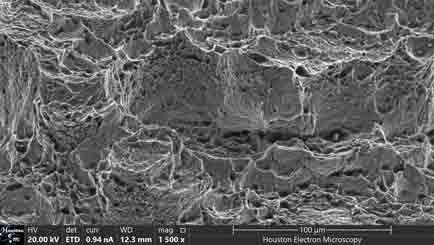

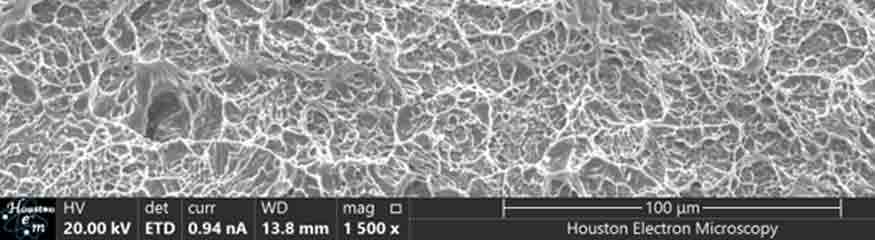

Ductile

Ductile

Ductile Failure

A ductile failure occurs in malleable materials, and is characterized by extensive plastic deformation or necking. This usually occurs prior to the actual failure of the material. In ductile failure, there is absorption of massive amounts of energy and slow propagation before the fracture occurs.

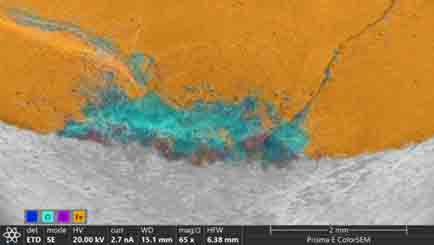

Fatigue origin. The blue area is remaining iron oxide in the initiation pit – 65X

Beach marks indicating fatigue failure

Fatigue Failure or Stress Fracture

Fatigue fracture occurs when a repeated force is applied and one or several cracks on the surface occur and spread inward until complete rupture suddenly occurs when the small unaffected portion is too weak to sustain the load.

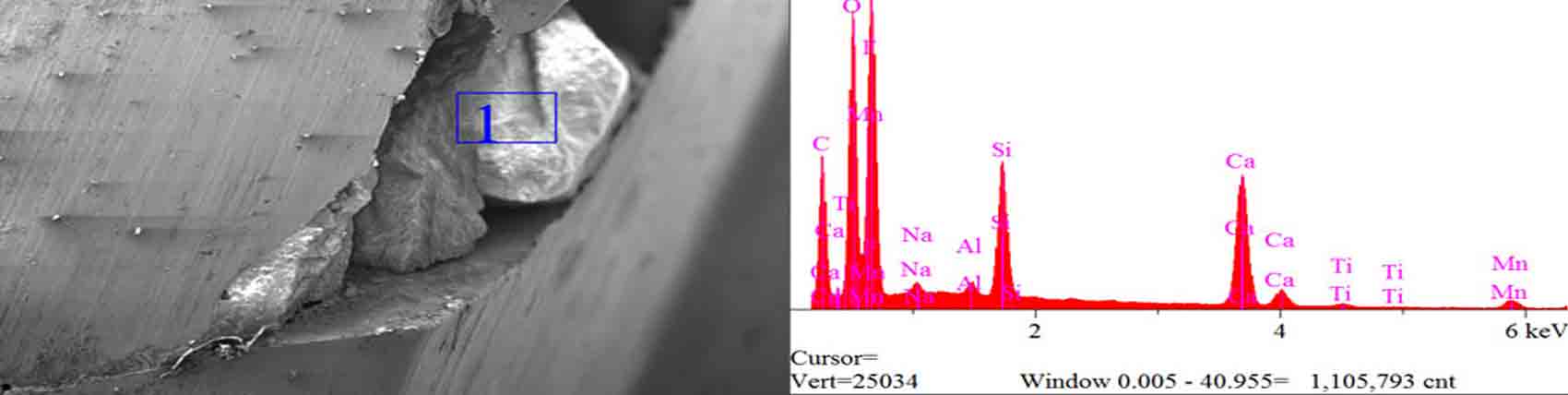

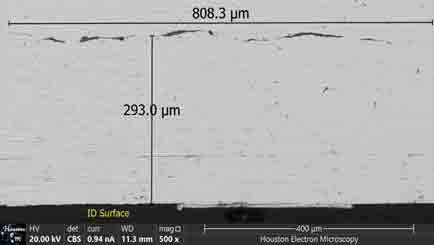

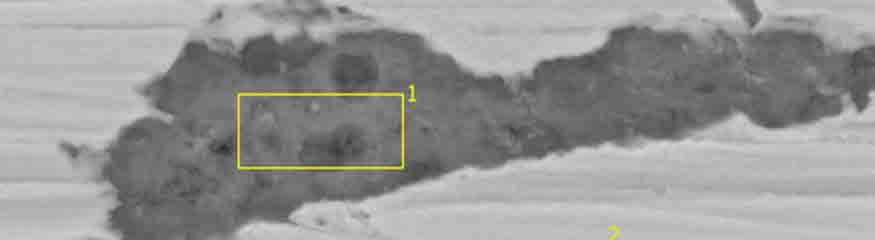

Identified inclusion in stainless steel

Identified inclusion in the stainless steel part analyzed further by EDS for identification of inclusion materials.

Inclusions or Flaws

Failure Analysis

Materials failure analysis is not just about identifying problems; it's about finding solutions and preventing future failures. By delving into the causes of failure, we make strides toward creating safer, more reliable materials and products that benefit industries and society as a whole. Our mission is to deliver efficient, cost effective answers to your materials problems through SEM/EDS services, and micro FT-IR analysis. Same day or next day service can usually be scheduled. We want to help metallurgists, materials specialists, manufacturers, engineers, quality assurance managers, attorneys, and designers find solutions to material and quality problems.