Houston Electron Microscopy Services

Scanning Electron Microscopy

The Scanning Electron Microscope (SEM) provides high magnification images at high-resolution of the sample surface and near-surface. Our SEM can operate in Low Vacuum mode, and in three different modes of Backscattered Electron imaging.

The SEM has many applications for many industries. Our expertise lies in failure analysis, PDC Analysis, Phase and Particle Analysis, Geological Core Samples, Corrosion, metallurgy, and coatings.

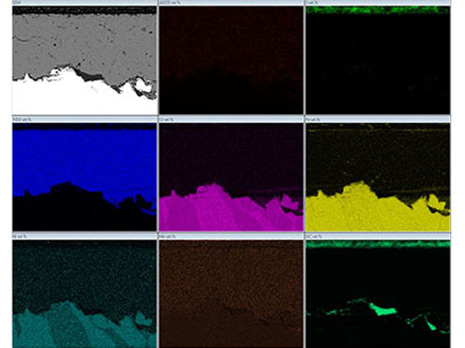

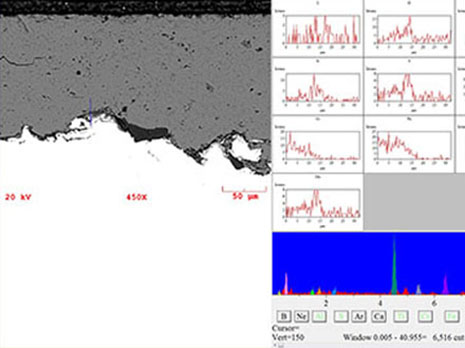

Micro Chemical Analysis (EDS)

Our Scanning Electron Microscope is paired with IXRF Systems, Energy Dispersive Spectrometer (EDS) with the latest SDD technology. The EDS is used for the elemental analysis or chemical characterization of a sample.

Qualitative and quantitative analysis as well as identification of unknown samples or inclusions is possible with the EDS. In addition, relative concentrations in weight, oxide, or atomic formula percentages can be obtained from the EDS spectra. Elemental and compound information can be viewed in several formats.

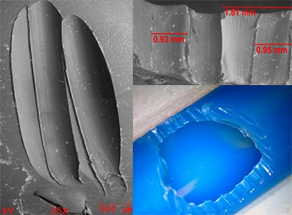

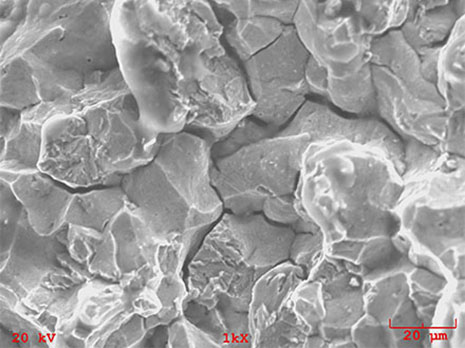

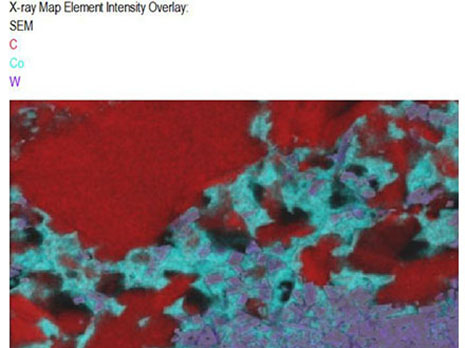

PDC Measurements and Analysis

The SEM/EDS is essential for looking at the physical structure, the leach depth dimensions can be measured, and with the EDS X-ray system an elemental map can be produced

Phase Analysis and Particle Analysis

The SEM is also widely used to identify phases based on qualitative chemical analysis and/or crystalline structure. Precise measurement of very small features and objects down to 50 nm in size can also be accomplished.

Contaminants Identification

Identifying contaminants is one of the many applications for our Scanning Electron Microscope and Element Dispersive X-ray system. Contaminants can be identified in solids and liquids, even oil.

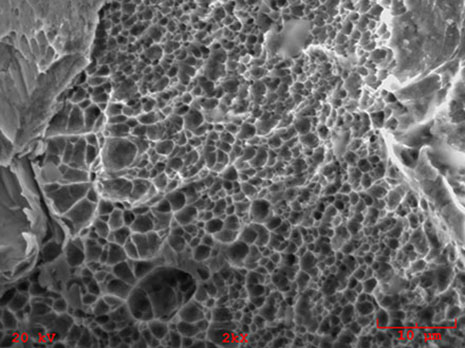

Geological Core Sample Analysis

Our SEM/EDS system has the ability to investigate small-scale textural features of shale and to characterize the organic particles and distribution of microporosity without having to add a conductive coating which may obscure the fine details of the sample surface.

Coatings Analysis

Thanks to the great depth of field, high magnification and high resolution possible with the SEM/EDS, Houston Electron Microscopy can help with the study and analysis of coatings.

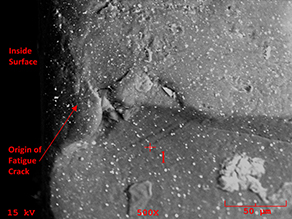

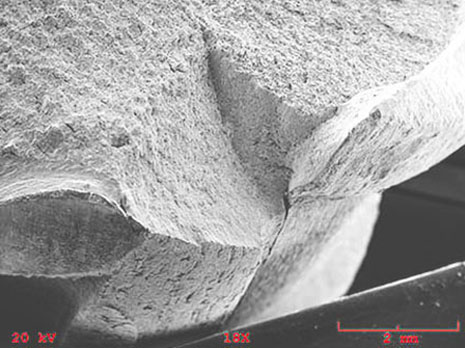

Metallography

Failure Analysis is one of our strong suits. Our SEM/EDX and metallograph are usually the only equipment need for most failure analysis. Houston Electron Microscopy is knowledgable in sample preparation for the metallograph and SEM.

Micro Structural Analysis

Microstructural analysis determins parameters such as coating thickness, grain size, porosity and pore structure, to full characterization of multi-component systems or evaluation of degradation or failure causes.

Gold Sputtering

Although the scanning electron microscope does not require gold sputtering, it is available at no extra charge.

Microhardness Testing

Micro hardness testing with Diamond Pyramid Hardness Tester (Vickers) can provide necessary data by measuring individual micro structures and determining the hardness gradient of a specimen along a cross section.

X-Ray Diffraction Analysis

X-ray diffraction (XRD) geathers information about the structure of crystalline materials for the identification and characterization of compounds based on their diffraction pattern.

Skilled SEM & EDX Services

Houston Electron Microscopy is able to conduct complete SEM/EDS analysis of metallic and non metallic componets. Expertise and range of experience is invaluable to our customers. Time is valuable and our star Failure Analysis Engineer, Dennis Manuel, has extensive experience which allow him to zero in on the problem quickly. He has the techniques and "know-how" to save you time and money. In addition, there are no "operator" or "engineer" fees.

Dennis has a diverse background in materials processing, scanning electron microscopy and failure analysis in various industries such as oil tool, petrochemical, heavy equipment, metallurgy, corrosion, heat treating, and welding. He has been in the field of metallurgy for over 30 years with most of those in analyzing failures and improving reliability. He earned a BS in Mechanical Engineering with a minor in Metallurgy from the University of Texas El Paso (UTEP); graduating summa cum laude and member of Apha Phi Beta.

Below is a list of services and some applications.

Services & Applications

- Failure Analysis of Metals

- Failure Analysis of Non Metals

- Metallography

- Geology

- Microstructural Analysis

- Element Analysis

- Element mapping

- PDC Measurement and Analysis

- Phase Analysis and Measurements

- Contamination Debris in Oil Samples

- Coating of plastics and metals analysis

We get answers

Houston Electron Microscopy

281-888-4261 or 281-704-0188

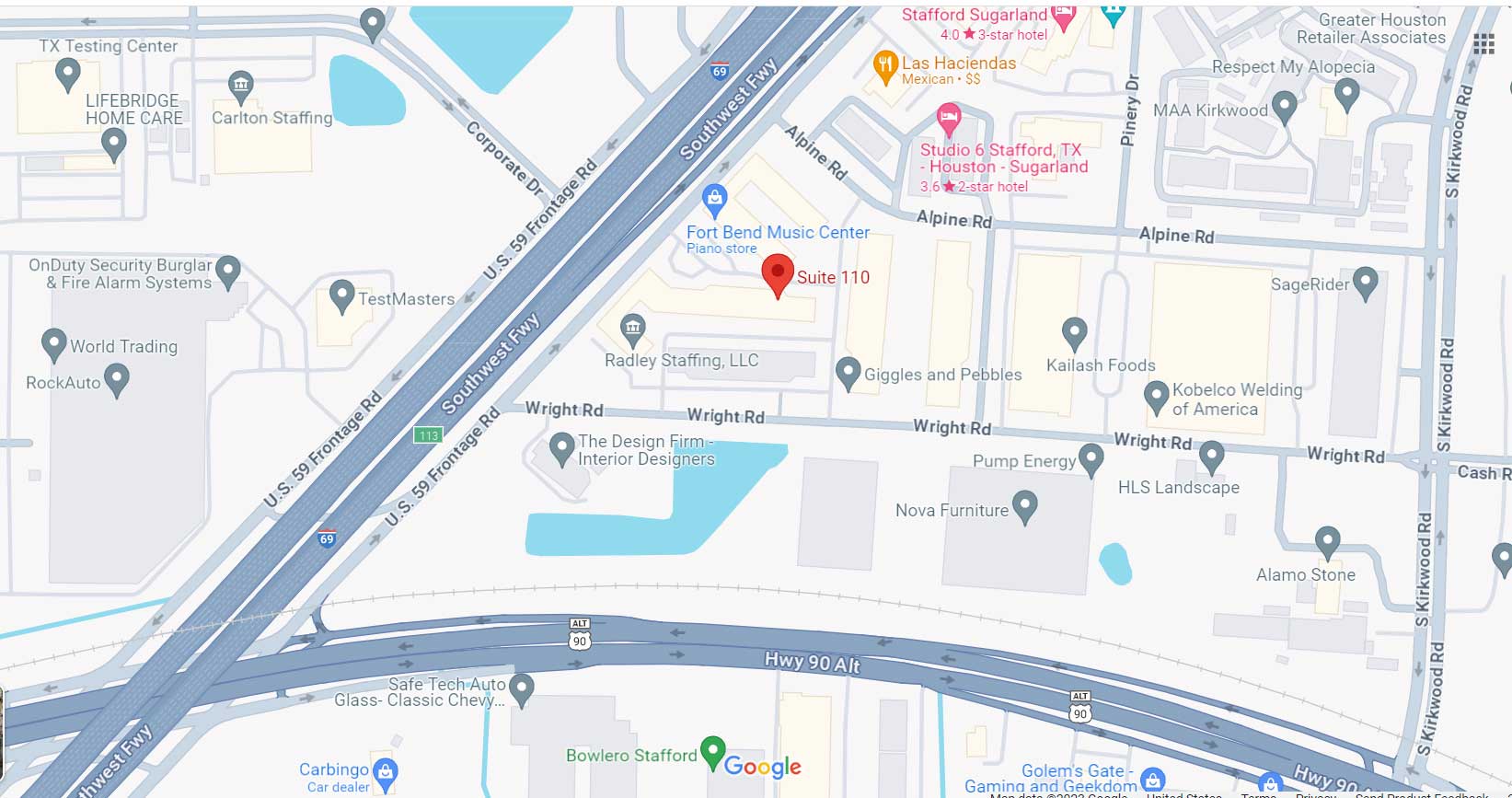

Close up of Our Location

We get answers

281.888.4261