SEM & EDS Services

Failure Analysis of Metals

Houston Electron Microscopy has the experience and specialized equipment to conduct complete microscopic failure analysis of metallic and non metallic materials. Our SEM/EDS system allows for non-destructive failure analysis by conducting a microscopic study of where failures initiate and help determine the cause or causes of failure. In mechanical failures, locating the origin is top priority. The origin can be found visually, but finding out the why and cause of the origin is where we come in. In failure analysis, the use of secondary imaging usually provides enough information to determine the mechanism of failure of a material. The EDS can identify the elemets in the material and identify if the failure is due to contamination or the material's element composition.

Our expertise and range of experience in failure analysis, fractography and corrosion analysis is invaluable to our clients.

The most common forms of material failures are fracture, corrosion, wear, and deformation. Material failures or fractures may be due to fatigue cracks, brittle cracks produced by stress corrosion cracking or environmental stress cracking. Sometimes failures may occur due to contaminants, or quality issues.

For failure analysis of metals and non-metals, our scanning electron microscopy laboratory has the sofistication and experience neccesary to find answers. Same day or next day service is available in most cases.

Failure Analysis of Metals

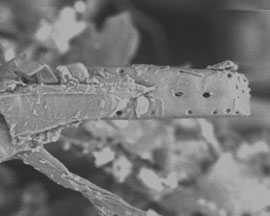

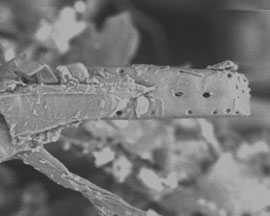

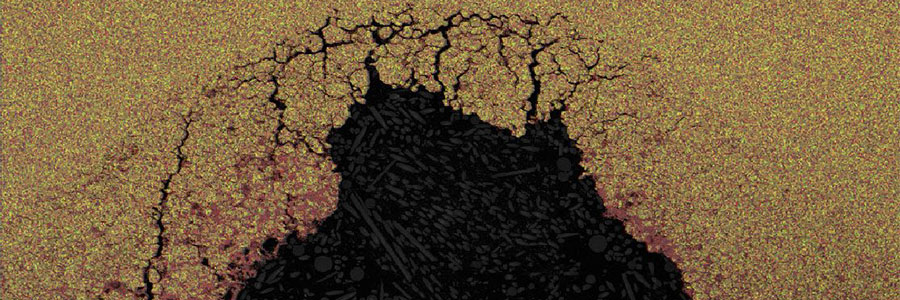

Fatigue Cracking

SEM examination of the fractures, wear surfaces, and corrosion deposits can lead to the cause of failure of many different metals.

Intergranular Cracking

Fracture surfaces of hard materials such as diamond aggregates (PDC) and WC can be examined for leach depth and phase distribution.

Brittle Cracking

With the Scanning Electron Microscope, coatings of any type can be examined to the finest detail for composition and morphology, thickness, porosity, layers, pinholes, etc.

Stress Corrosion Cracking

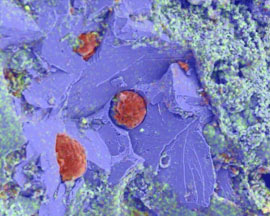

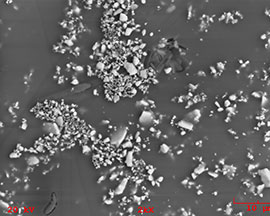

Image of a diatom among dust particles. Our Scanning Electron Microscope system is capable of imaging at high magnification with a deep field of focus.

Failure Analysis - Plastic and non-metals

xxx

Environmental Stress

Image of a diatom among dust particles. Our Scanning Electron Microscope system is capable of imaging at high magnification with a deep field of focus.

Failure Analysis - Plastic and

Experience in Failure Analysis and Materials

Our primary goal is to get you the answers to your materials problems.

Example Applications

- Failure Analysis

- Fracture surface characterization

- Corrosion deposit analysis

- Geological specimen and core analysis

- Coatings analysis and characterization

- Phase and particle analysis

- Polycrystalline Diamond Compact (PDC) analysis

- Particle contamination in oils

- Identification of process abnormalities

- Contaminant investigations

- Microstructural defect analysis

- Reverse engineering

- Welding engineering analysis

OTHER SERVICES

- Metallography

- Micro-hardness Testing

- X-Ray Diffraction

- FTIR analysis of organic materials

- Experience

- Modern SEM/EDS System

- No hidden charges

- Easy and quick availability

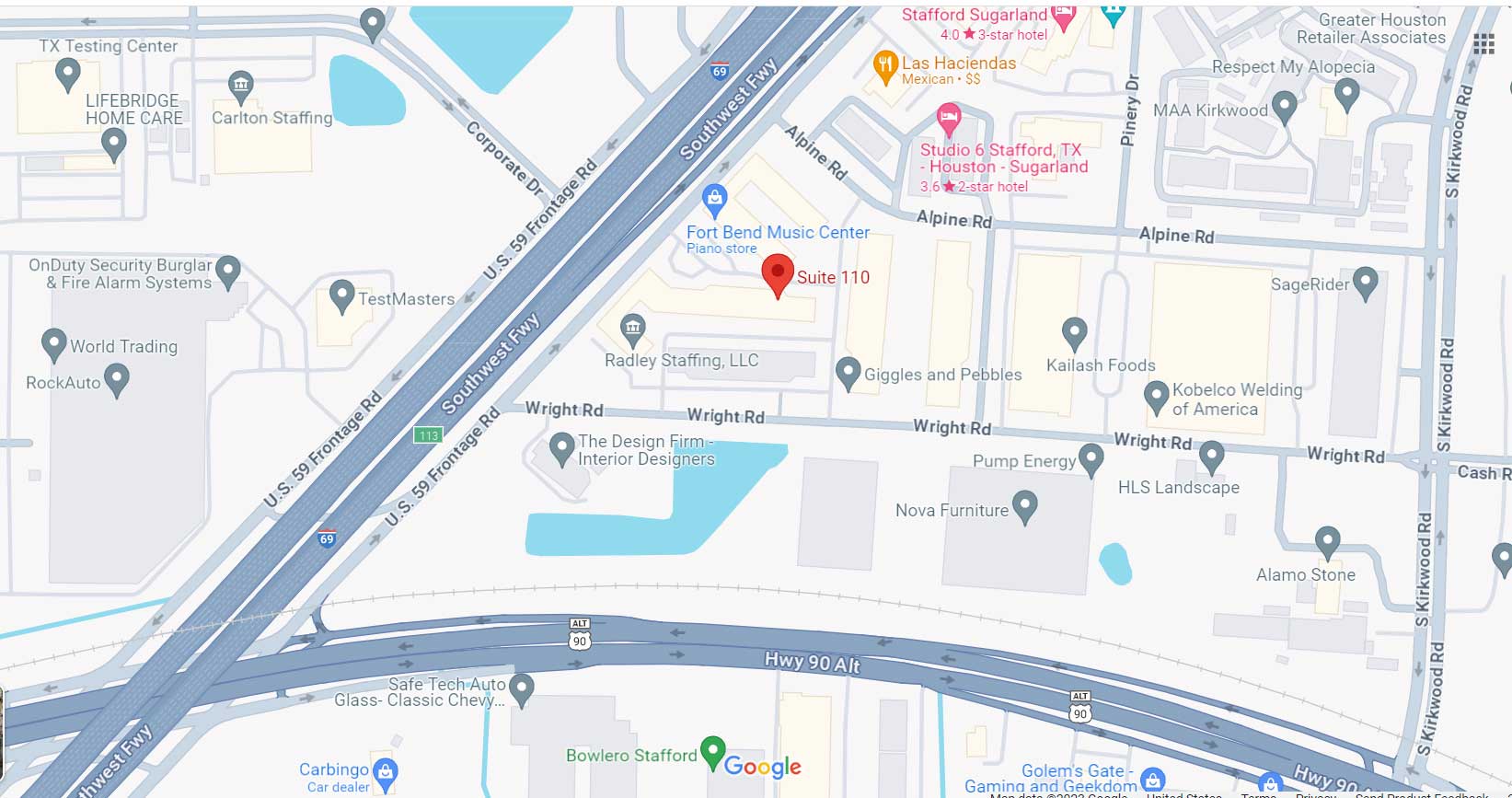

- Conveniently located in Northwest Houston

Advantages

We get answers

Houston Electron Microscopy

281-888-4261 or 281-704-0188 Fax:1.888.600.0212

Toll Free: 1-844-318-8775

Close up of

Our Location, (PDF file)

We get answers

281.888.4261

Toll Free: 1-844-318-8775